Concrete Pumping Machinery: Types, Uses and Buying Guide

-

Thesis: Choosing the right concrete pump is critical for efficient, safe, and cost-effective placement; understanding the types, capabilities, and selection factors is essential.

-

Outline:

-

Fundamentals: How concrete pumps work (hydraulic systems, valves – S-Valve vs. Rock Valve).

-

Types Deep Dive:

-

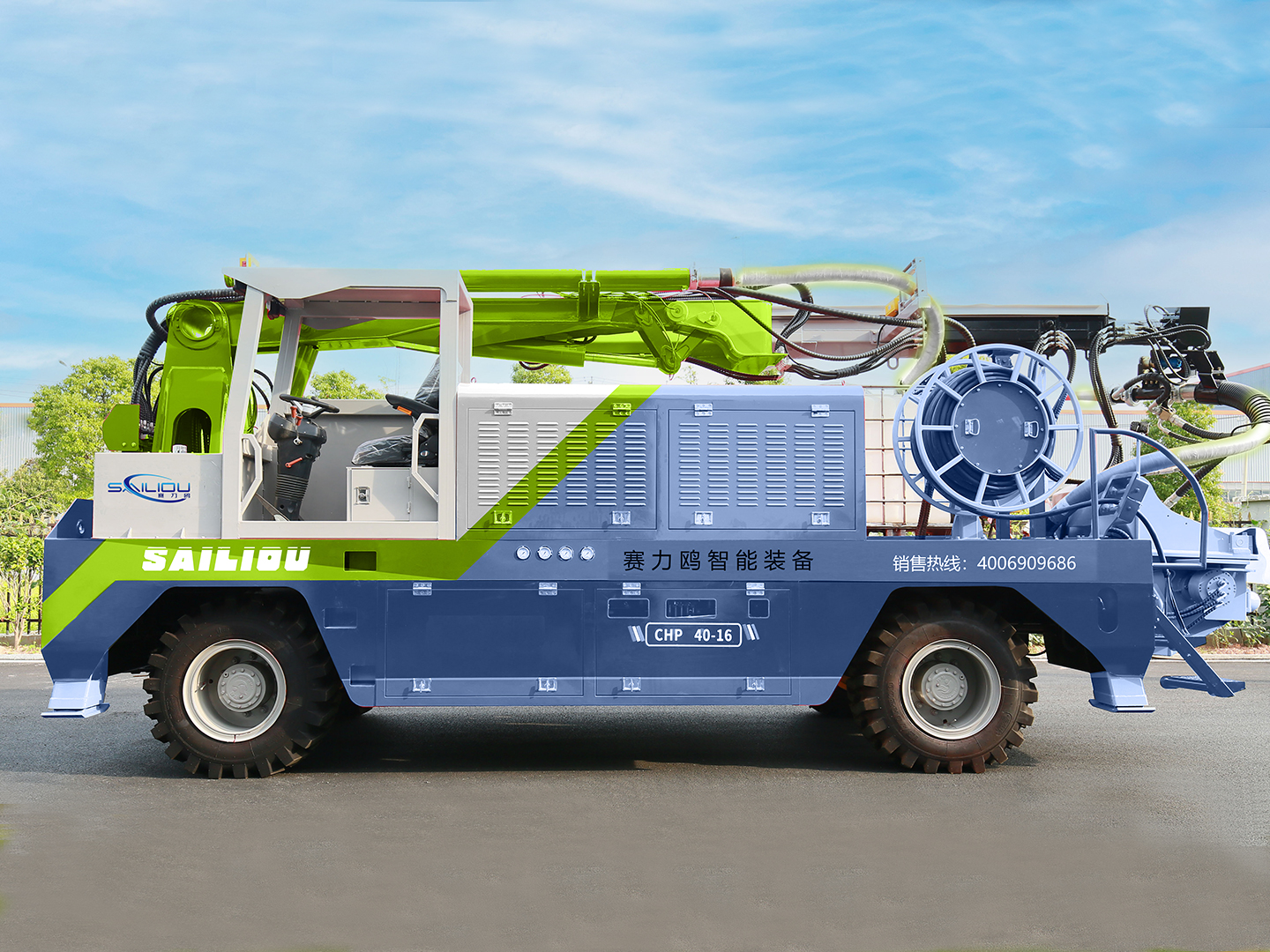

Boom Pumps: Mounts (Truck, Trailer, Rail), Reach (Meters), Output (Cu Yd/Hr), Placing Width. Uses: High-rises, large slabs, bridges. Pros: Reach, speed. Cons: Cost, setup space.

-

Line Pumps (Trailer/Putzer): Ground placement. Output, Max Pressure (PSI/Bar), Versatility (Wet shotcrete, grout). Uses: Slabs, foundations, pools, remote sites, shotcrete. Pros: Maneuverability, lower cost. Cons: Manual pipe handling, slower than booms for large volumes.

-

Specialized Pumps: Separate placing booms (for fixed pumps), industrial pumps for high-pressure/long-distance, shotcrete pumps (wet/dry).

-

-

Key Selection Factors:

-

Project Requirements: Height/Reach needed, volume, concrete type (SCC, aggregate size), site access/space.

-

Pump Specs: Max theoretical/actual output, max pressure, boom configuration/placing width (for booms), pipe diameter.

-

Power Source: Diesel (standard), Electric (growing), Hybrid.

-

Features: Remote control, diagnostics, safety systems (load monitoring, emergency stop), ease of cleaning.

-

-

Operation & Safety: Operator training/certification, pipe setup/inspection, communication protocols, understanding pump limitations, critical safety rules (never modify/remove guards, clear hopper blockages safely).

-

Buying Considerations: New vs. Used (see Article 16), rental options, dealer support, parts availability, TCO analysis.

-

Specifications & Guideline

Specifications & Guideline