Sailiou YD-300APM/YSBPY-36/7 Compressor

The Sailiou permanent magnet two-stage variable frequency mobile air compressor is a new model specially designed and manufactured by our company for the use environment and working conditions of domestic medium and long tunnel air compressors.

It adopts the industry-leading permanent magnet motor + two-stage compression host + inverter control + wheeled mobile chassis.

Technical parameters of permanent magnet two-stage variable frequency mobile screw air compressor

Advantages and features of permanent magnet two-stage variable frequency mobile screw air compressor

① More energy-saving and power-saving:

Using permanent magnet variable frequency technology + two-stage compression host, low-speed, fully enclosed motor, smooth start-up, no impact on the power grid. Compared with the industrial frequency twin-screw air compressor, it can save up to 25% energy.

② Cost saving:

The air compressor can be placed next to the gas-using equipment for use by using wheeled mobile mode, which can reduce the construction cost of the air compressor room and the investment cost of the air duct pipeline.

③ Reduce gas loss:

During the tunnel construction process, the traditional method adopts centralized gas supply. The air compressor room is arranged near the cave entrance and gas supply is achieved through pipeline connection. Generally, the gas loss of 1,000 meters of tunnel construction is about 30%; the gas loss of 2,000 meters of pipeline is about 50%. After using a mobile air compressor, lossless gas supply can be basically achieved.

④ Reduce registration procedures:

Mobile permanent magnet variable frequency screw air compressor does not need to install gas storage tanks, which can reduce the cumbersome registration procedures such as gas storage tank inspection and installation.

| Model | Rated exhaust volume | Rated working pressure | Machine weight | Exhaust port | Dimensions | |

| m2 /min | MPa | kg | Size | (L x W x H mm) | ||

| YSBPY-36/7 | 36 | 0.7 | ≈3800 | G1, G2 | 3400X2100X2500 | |

| Motor power | Power range | Starting mode | Cooling method | Drive mode | Ambient temperature | Protection insulation grade |

| KW | KW | |||||

| 160 | 37~160 | Variable frequency | Air cooling | Direct connection | -5~+45 | IP55/F |

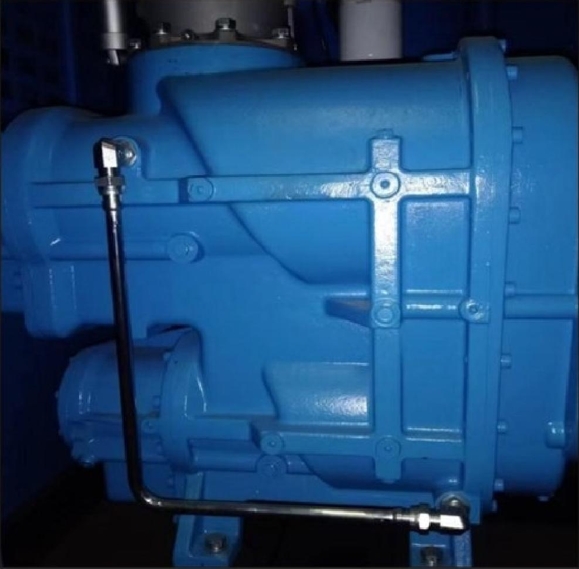

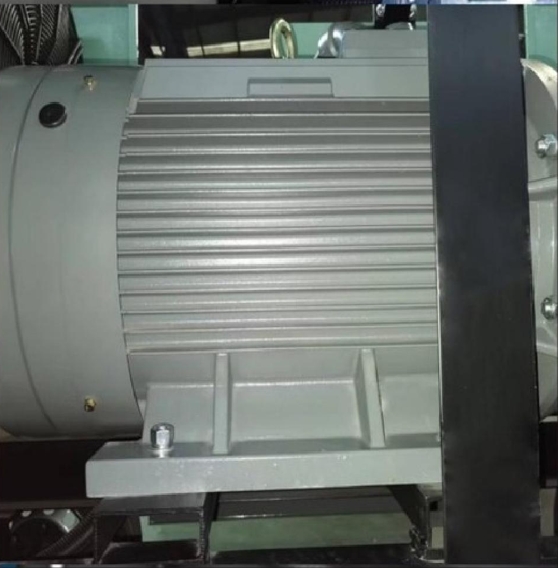

INTERNAL PHOTOGRAPH OF AIR COMPRESSOR

Dual-stage host

Fully enclosed permanent magnet motor

Frequency Controller

Matters Needing Attention in Equipment Installation

1. Construction environment: The relative humidity of the air should be low, with less dust, clean air and good ventilation.

2. Ambient temperature: must be lower than 45℃. The higher the ambient temperature, the less air the air compressor outputs

3. If the construction environment of the construction site is poor and there is a lot of dust, a pre-filter must be installed. It is recommended to switch to industrial frequency start.

| Model | Rated exhaust volume | Rated working pressure | Machine weight | Exhaust port | Dimensions | |

| m2 /min | MPa | kg | Size | (L x W x H mm) | ||

| YSBPY-36/7 | 36 | 0.7 | ≈3800 | G1, G2 | 3400X2100X2500 | |

| Motor power | Power range | Starting mode | Cooling method | Drive mode | Ambient temperature | Protection insulation grade |

| KW | KW | |||||

| 160 | 37~160 | Variable frequency | Air cooling | Direct connection | -5~+45 | IP55/F |