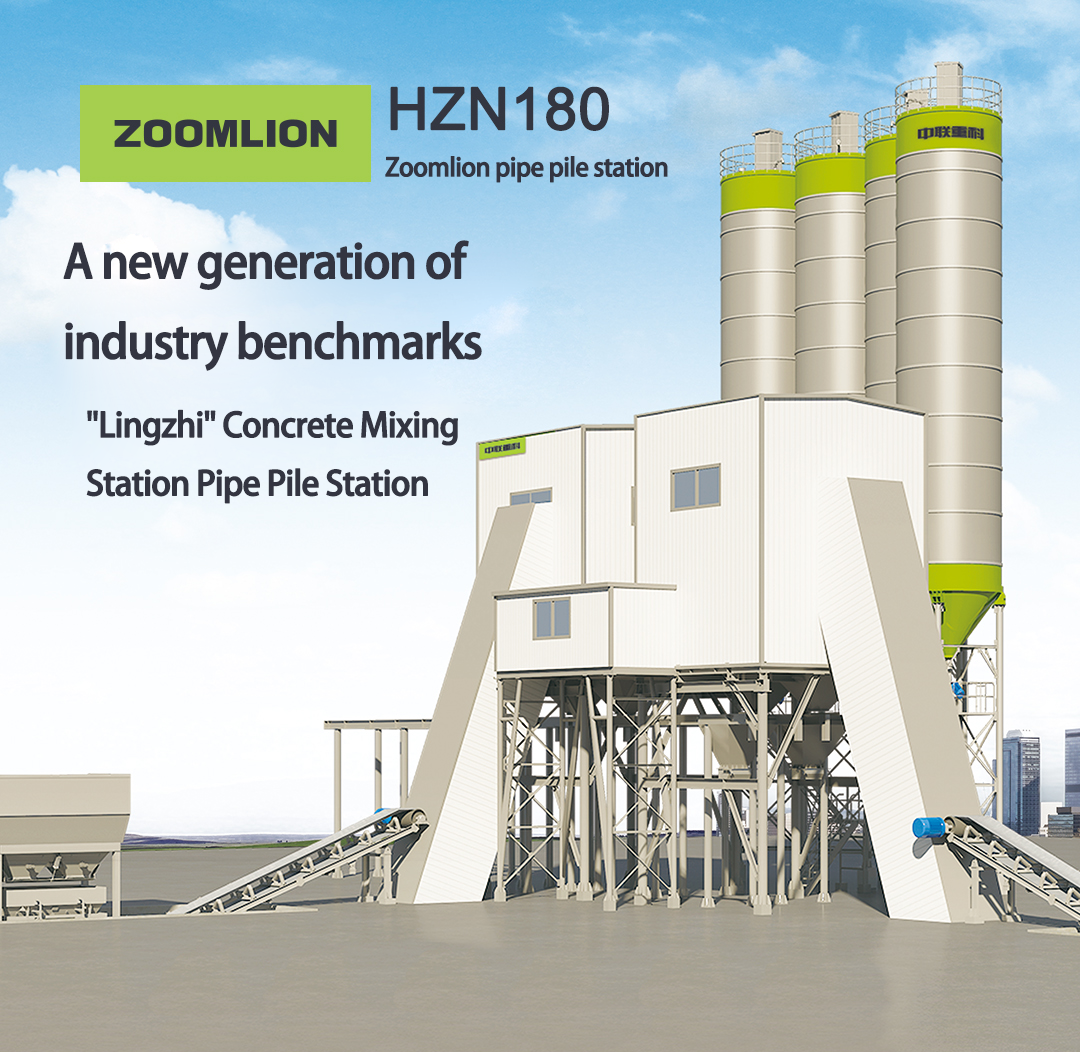

ZOOMLION HZN180 pipe pile station

ZOOMLION HZN180

Zoomlion pipe pile station

The new generation of industry benchmark "Lingzhi" concrete mixing station - pipe pile station

1 High efficiency and energy saving

Vertical shaft mixing main machine, planetary transmission principle, the mixing arm has both rotation and revolution, high mixing efficiency; there is no mixing inefficient zone and dead zone, and the mixing uniformity is better. The comprehensive load rate is low and more energy-saving.

2 Convenient and reliable

Equipped with two independent discharge ports for discharging materials, it is convenient for the double-track trolley to receive materials; it adopts double steel wire rope traction to extend the service life by 50%.

3 Easy to maintain

The floor area ratio is low and the internal space is large; the double access doors facilitate the maintenance of internal components. The tipping bucket discharge structure completely solves the problem of material spreading and accumulation.

4. Small footprint

The lifting bucket is used for loading, which saves 40% of the floor space compared with belt conveyor loading.

1. The product images, technical parameters, and configurations on the above pages are for illustration only. The actual product effects (including but not limited to appearance, color, size) and technical parameters and configurations may vary slightly. Please refer to the actual product for accuracy; Additionally, the machine in the picture may include additional equipment.

2. The data on the above page are theoretical values obtained from the internal laboratory of Zoomlion Heavy Industry Science and Technology Co., Ltd. under specific testing environments. Actual use may vary slightly due to individual differences in products, usage conditions, and environmental factors. Please refer to the actual usage situation.

3. In order to provide as accurate product information, specifications, and features as possible, Zoomlion may adjust and revise the text descriptions, image effects, and other content on the above pages in real time to match the actual product performance, specifications, indices, components, and other information.

4. Due to real-time changes in product batches and production supply factors, in case of necessary modifications and adjustments, no special notice will be given. Please refer to the official website for real-time information.

| Model | Commercial mixing series | Commercial mixing overhead mixing station | Commercial mixing floor series | |||||||||||

| project | unit | HZS120 | HZS180S | HZS240S | HZS270S | HZS300S | HZS180STop-mounted | HZS240STop-mounted | HZS270STop-mounted | HZS300STop-mounted | HLS180E | HLS240E | HLS270E | HLS300E |

| theoretical productivity | m3/h | 120 | 180 | 240 | 270 | 300 | 180 | 240 | 270 | 300 | 180 | 240 | 270 | 300 |

| Mixer model | JS2000 | JS3000 | JS4000 | JS4500 | JS5000 | JS3000 | JS4000 | JS4500 | JS5000 | JS3000 | JS4000 | JS4500 | JS5000 | |

| Stirring motor power | kW | 2X37 | 2x45 | 2X55 | 2X75 | 2X75 | 2x45 | 2x55 | 2X75 | 2X75 | 2x45 | 2x55 | 2x75 | 2x75 |

| The largest particle size of aggregate | mm | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 |

| theoretical production cycle | s | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Feed capacity | L | 3000 | 4500 | 6000 | 6750 | 7500 | 4500 | 6000 | 6750 | 7500 | 4500 | 6000 | 6750 | 7500 |

| Discharge capacity | L | 2000 | 3000 | 4000 | 4500 | 5000 | 3000 | 4000 | 4500 | 5000 | 3000 | 4000 | 4500 | 5000 |

| Aggregate bin capacity (optional) | m3 | 4x20 | 4x25 | 4x25 | 4X30 | 4X30 | 4x25 | 4X25 | 4X30 | 4X30 | 200 | 200 | 200 | 200 |

| Powder bin capacity (optional) | t | 4X150 | 4x300 | 4X300 | 4X300 | 4X300 | 4X300 | 4X300 | 4x300 | 4x300 | 4x300 | 4x300 | 4x300 | 4x300 |

| Batching station batching capacity | L/Can | 3200 | 4800 | 6400 | 7200 | 7200 | 4800 | 6400 | 7200 | 7200 | / | / | / | / |

| Belt conveyor conveying capacity | t/h | 900 | 900 | 900 | 1500 | 1500 | 900 | 900 | 1500 | 1500 | 600 | 600 | 600 | 600 |

| Screw conveying capacity (cement) | t/h | 60 | 90 | 110 | 120 | 180 | 165 | 165 | 165 | 165 | 90 | 110 | 150 | 150 |

| Discharging height | m | ≥4 | ≥4 | ≥4 | ≥4 | ≥4 | ≥4 | ≥4 | ≥4 | ≥4 | ≥4 | ≥4 | ≥4 | ≥4 |

| Installed capacity | kW | 185 | 225 | 265 | 335 | 350 | 205 | 235 | 305 | 305 | 295 | 325 | 390 | 390 |